-40%

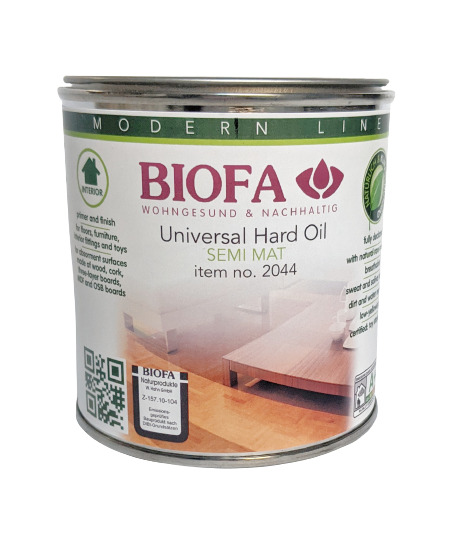

BIOFA Universal Hard Oil (2044) .375L / Non-Toxic Wood Sealer / Natural Wood Oil

$ 16.1

- Description

- Size Guide

Description

BIOFA Universal Hard Oil 2044.375L

semi-gloss

BIOFA Universal Hard Oil 2044 is made from natural raw materials. It is

is a high-quality, versatile, colorless wood preservative oil for parquet and cork floors, but also for linoleum floors, stairs, wooden furniture, Sterling OSB boards, wooden interior fittings and other wooden items.

The oil revitalizes the natural structure of the respective material and, thanks to its thin surface film, results in an open-pored, satin-matt, hard-wearing, dirt- and water-repellent surface that is largely non-yellowing.

BIOFA Universal Hard Oil complies with stringent European regulations such as EN 71, part 3 and 9, DIN 53160, and DIN 14342.

Technical Data and Safety Data Sheets available upon request. The below is from the Technical Data Sheet:

Properties

Premium natural resin-oil concentrate from natural raw materials. It rejuvenates the natural structure; the thin surface film results in an open-pore, semi-glossy, durable, and water-repellent finish that is especially resistant to yellowing. Meets EN 71, part 3 (safety of children's toys) and DIN 53160 (perspiration and saliva color fastness). BIOFA Universal Hard Oil is suited for absorbent surfaces for indoor applications like wood, cork, and linoleum flooring, stairs, wood furniture, Sterling OSB panels, and interior built-ins. Not suited for continuous moisture exposure!

Attention

: Odors may form if used on interior furniture surfaces! BIOFA Universal Hard Oil 2044 was tested for anti-slipping properties pursuant to Swiss bfu/EMPA criteria and has the following GS values: Rubber, smooth: GS 2; Rubber, fine grooves: GS 3; Plastics, rough grooves: GS 2; Leather, smooth: GS 1. BIOFA Universal Hard Oil meets the requirements of the parquet standard DIN EN 14342 DIBt approval number: Z-157.10-104

Ingredients

Aroma-free, highly-purified white spirit, ricin oil - colophony resin blend, safflower oil, colophony resin solution, matting agents, swelling clay, micro-wax, zinc oxide, cobalt-polymer drying agent, zirconium, calcium, and manganese drying agents, antioxidant.

Processing steps:

1. Preparation Substrates must be dry (max. wood moisture content: 12 %), absorbent, grease-free and clean; clean with thinner 0500 as needed. Remove old paint coats. Finish sand with 240 grit on furniture surfaces, with 120 grit on flooring.

2. Base coat Thoroughly mix universal hard oil; then apply an even and thin coat by brushing, rolling, spraying dipping, barreling, or wiping. For floor applications, it is best to work with a short-pyled velour roller. Primer highly absorbent and color-burned substrates with BIOFA Universal Wood Primer 3755 solvent-free. For flooring applications, a primer coat with BIOFA Universal Wood Primer 3755 solvent-free is generally recommended to minimize solvents.

3. Intermediate and topcoats Following the first hard primer or hard oil coat, sand between coats (flooring: 150-180 grit screen, furniture and interior built-ins: 240 grit). Flooring from wood and cork are given at least 2 finish coats with BIOFA Universal Hard Oil. If only BIOFA Universal Hard Oil is used, apply 2-3 thin coats depending on substrate absorption. The first coat can also be padded in. Sand between coats as needed. Another hard oil coat may be required for any resulting uneven finishes, or on highly absorbent and high-traffic substrates. The finish is only fully durable if the film has been fully formed and has sufficient thickness Apply 1 to 2 thin coats of BIOFA Universal Hard Oil on uncoated linoleum floors.

Important: Mix containers from different batches before processing! Be sure to test product before proceeding! Ensure sufficient fresh air circulation when processing and drying the products! Failure to observe these instructions may result in long-term odor exposure. Do not use below 12°C!

Spraying application data

Spraying: Cup gun with compressed air: Nozzle: 1-1.5 mm, spray pressure: 2-2.5 bar. Airless: Nozzle: 0.23-0.28 mm, spray pressure: 4 bar, material pressure: 80 bar.

4. Equipment cleaning Clean immediately after use with BIOFA Thinner 0500.

5. Cleaning and caring for the finish Dry cleaning with soft broom, rag, mop, or vacuum brush. For wet cleaning, use a ph-neutral, mild cleaning agent in lukewarm water. We recommend NACASA Universal Cleaner 4010. See special care instructions for floor surfaces!

Drying

BIOFA Universal Hard Oil is dust-dry after 6-12 hours and can be sanded and coated over after 16-24 hours. Floors are subject to limited use after 3 days, unrestricted use after 7-10 days. (20°C / 50-55 % rel. humidity). Heating and good air circulation will accelerate drying. Low temperatures, high ambient humidity or substrate moisture and tannin-rich woods, tropical woods, and cork may inhibit drying.

Consumption/yield

Construction codes (DIBt) require that a primer coat with Universal Hard Primer solvent-free 3755 must be followed by two coats of Universal Hard Oil 2044 with 25 g/m² or 28 ml/m² each. The following consumption quantities and yields apply if only Universal Hard Oil 2004 is used: 1st coat: approx. 60-80 ml/m² or 12-16 m²/l. 2nd and 3rd coat each 45-60 ml/m² or 16-22 m²/l. An additional coat may be required on highly absorbent substrates or in high-traffic areas. Consumption and yield greatly depend on the absorption and condition of the substrate. Storage Keep cool, dry and properly sealed. May form skin. Remove before next use. Screen oil as needed! Container 0.375 l / 0.75 l / 2.5 l 10 l | 30 l metal containers

Hazard warnings

Poisonous for water organisms with long-term effect.

Safety instructions

Store processing materials and clothing soaked with product in air-tight metal containers, or soak in water, then spread out and allow to dry on noncombustible ground ––(risk of spontaneous combustion!) The product itself is not autoignitable. Keep away from children. WHEN INGESTED: Immediately call POISON INFORMATION CENTER or get medical help. DO NOT induce vomiting. Read label before use. Do not inhale vapor/aerosol. When sprayed, ensure adequate vacuum collection and respiratory protection. Only use in properly ventilated areas. Explosive vapor/air mixtures can be generated when heated or sprayed! Ensure adequate skin protection when processing. Wear fine particulate mask when sanding! Avoid release into the environment. The natural ingredients may generate an odor typical for the product!

Disposal

Deposit liquid product leftovers at a collection point for old paints/old varnishes, and/or dispose in compliance with local statutory regulations. Minor leftovers and soaked processing materials can be disposed in the household waste after drying out. Only recycle fully emptied and cleaned containers. Not completely emptied and cleaned containers must be treated and disposed like the product! German Waste Classification Directive [Abfallverzeichnis Verordnung - AVV] waste code law. European waste classification: 08 01 11*

VOC labeling law.

Decopaint directive and ChemVOCFarbV: EU threshold (Cat. A/i): 500 g/l (2010) 2044 contains max. 490 g/l VOC GIS CODE: Ö 60+